Custom Cabinets & Wardrobes | Professional Solutions for Homes & Hotels

We specialize in creating custom cabinets designed to enhance your home and display your art collection. Our team works with you to design cabinets that fit your style and needs, helping you turn your space into a beautiful showcase. Let us help you elevate your home with functional and stylish cabinetry.

- Home

- Kitchen Cabinet&Wardrobe

Custom Cabinets for Residential & Commercial Spaces

Custom Cabinets For Kitchen Area

Kitchen Cabinets

Learn about our all-in-one solutions for custom cabinets, from its countertop styles, functional appliance layouts, its body and panel materials, and versatile hardware to create an efficient kitchen that combines culinary pleasure with practical function. Our design and product teams will customize your commercial or residential kitchen space based on your cabinetry needs!

Custom Cabinets For Bedroom Area

Wardrobe

Learn about our all-in-one solutions for custom wardrobe, from closet panel selection, functional area layout, materials used in the body of the closet, to multi-functional hardware, to create an exclusive closet that is aesthetically pleasing and practically functional in one. Our design and product teams will customize your commercial or residential closet space based on your closet needs!

Custom Cabinets For Living room Area

Living Room Cabinets

Learn about our custom living room cabinets to create an exclusive living room area that combines beauty and practicality, from its panel selection, functional area layout, and body materials to versatile hardware. Our design and product teams will customize your commercial or residential living room cabinet space to fit your cabinet needs!

Custom Cabinets For Laundry Area

Laundry Cabinets

Learn about our balcony cabinets to create an exclusive balcony cabinet that combines beauty and practicality, from cabinet panel selection, functional area layout, cabinet body materials to versatile hardware. Our design and product teams will customize your commercial or residential balcony cabinet space based on your cabinet needs!

Guide to Custom Cabinets to Meet Your Exact Specifications

Step 1 Schedule

Step 2 Function

Step 3 Budget

Step 4 Production

Upon approval of the final design, we will initiate production planning in our workshop. This includes material cutting, machining, assembly, and quality inspection, ensuring each operation aligns with the design specifications. Once the production is complete, we will promptly send you photos of the finished products for your confirmation, ensuring that all items meet both quality standards and your requirements.

Common Custom Cabinet Raw Material

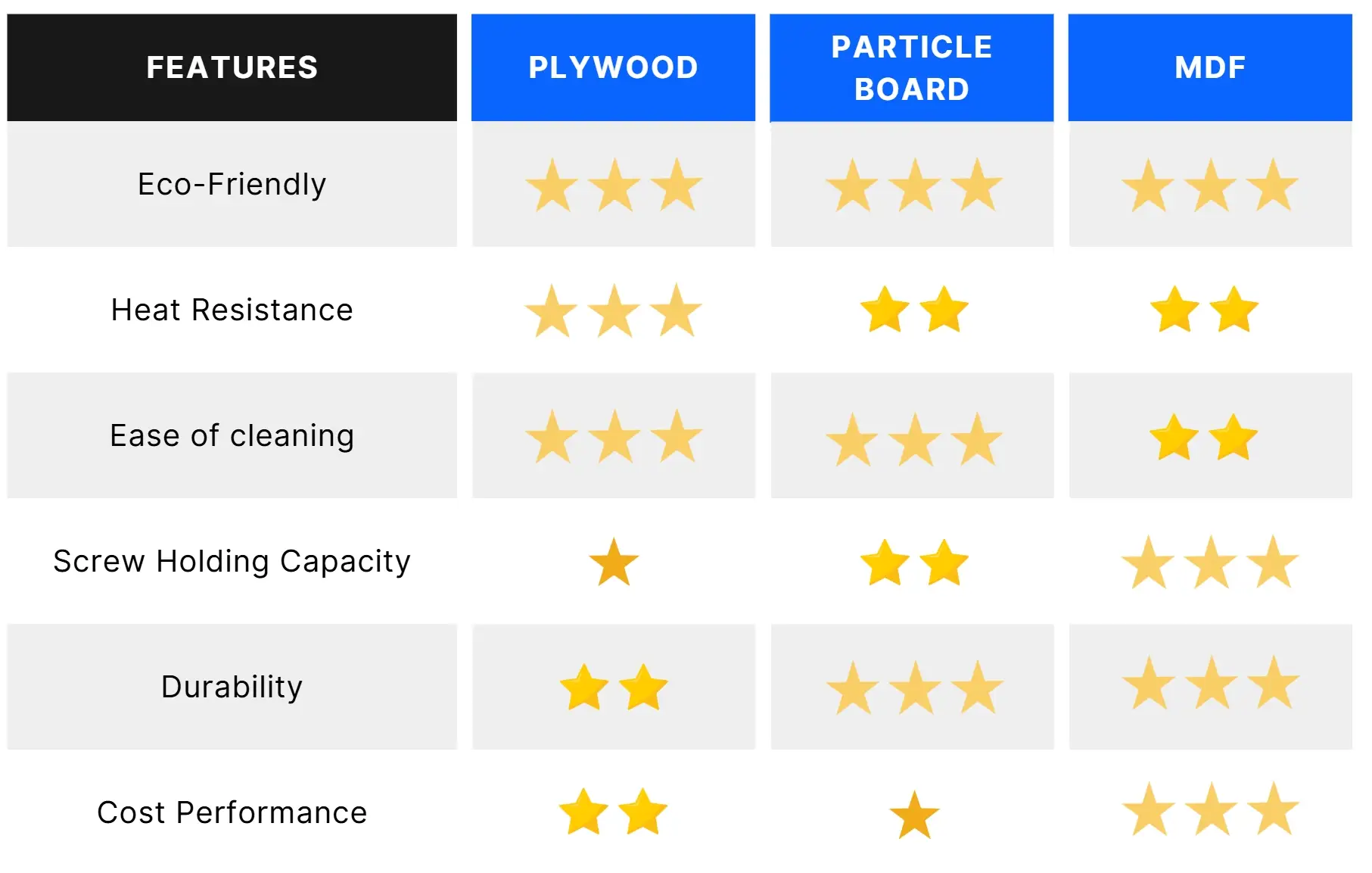

Comparative Properties of the Three Fundamental Materials

Why Choose George Custom Cabinets

George Cabinet Department with a workforce of 150 employees and a 50-acre manufacturing facility equipped with state-of-the-art production equipment, has been specializing in the design, manufacture, and distribution of kitchen cabinets, wardrobes, bathroom vanities, and other cabinetry for over 16 years. We take pride in collaborating with end-users and engaging with architects, developers, builders, and contractors globally on a diverse range of projects, consistently delivering high-quality work and exceptional services to our clients.

Client Cases In George Cabinet Department

Bespoke cabinets FAQS

Yes, There are a variety of material options available. Our primary considerations include environmental protection, durability, aesthetics, moisture resistance, cost, and ease of maintenance.In addition to the aforementioned three commonly used materials, there are also metal options such as stainless steel and aluminum alloys, as well as wood varieties including oak, pineapple, and walnut.

Different materials have their own advantages and disadvantages, applied in different places to give fuller play to its performance, the following is our summary of several points:

1. Plywood

As we described above,plywood combines the natural qualities of wood with added benefits. It is easy to shape, resists deformation and cracking, and has good waterproof and moisture-resistant properties.Its properties make it more suitable for sturdy furniture, ceilings and back panels of cabinets, etc.

2. Particle Board

The raw material properties of particleboard give it a wide, flat surface with strong support and a good nail grip. This makes it durable and less likely to warp during custom cabinetry or installation. Its surface bonds well to stains and finishes. We use environmentally friendly materials and processes to make particleboard a sustainable choice for both the environment and your home. Suitable for cabinet and door base materials and load-bearing panels (laminates, side panels)

3. MDF(Medium density fiberboard)

MDF is similar to particleboard but generally has slightly lower dimensional stability and surface quality. However, MDF is easier to work with and more affordable due to its cost-effective materials.It is more commonly used as a door substrate for kitchen cabinets and wardrobes.

4.Metal Materials (Stainless Steel,Aluminum alloy)

Metal cabinets are durable, moisture-proof, fireproof, and easy to clean, making them ideal for high-humidity areas like kitchens and bathrooms. However, metal cabinets are often less attractive and more expensive compared to traditional wooden options, such as solid wood or man-made panels

5.Solid wood (a collective term for different woods)

Cabinets can be made from many kinds of solid wood, such as pine, cherry, white oak, red oak, red cherry, and rosewood. Each type has a unique grain and texture, and they are known for their strength and durability.

While solid wood can be painting to enhance its appearance in production, it is generally more expensive and sensitive to changes in humidity and temperature. As a result, it may crack or warp and is not ideal for use in bathrooms or outdoor areas.

Should you require further assistance in making a decision, please do not hesitate to contact us. We will be pleased to offer recommendations tailored to your style and usage requirements.

No problem at all. Many of our customers start with cabinet designs they find online. We can adjust these designs to fit your style and needs. If you’re still not satisfied, we have a catalog of various cabinet styles for you to choose from. Keep in mind that online images may look slightly different from the actual product due to color variations. We’ll provide you with a 3D rendering to help you visualize the final look before we begin production and send you photos for approval once it’s done.

Thank you for your attention to this matter. Customizing your cabinets and completing your order requires two key steps:

1.Customized cabinetry for new construction projects

For the arrangement of unassigned spaces, our team of professional designers will utilize your floor plan and cabinet requirements to develop a 3D rendering program. This will help visualize your interior’s cabinetry needs. Once you approve the overall design, we will provide a detailed quotation and compile the volume and weight of the goods to give you a precise estimate of the total order cost.

2.Refurbishment of existing cabinets

If you provide us with the original floor plan of your residence, we can develop a design plan tailored to your cabinetry needs, including specifications for color and size. Upon completion of the design, you will review and confirm the details. We will then update the original cabinetry based on the dimensional data from the new plan, and finalize the quotation based on these modifications.

In the absence of an original floor plan, we can still develop a comprehensive design plan, incorporating color and size specifications, based on the dimensions of your existing cabinetry. To facilitate this process, you will need to complete a measurement task.

We will provide either a video guide or a detailed graphic tutorial to assist you with the measurement process. Ideally, your remodeling team can assist with this task.

Once all product details and costs are accurately confirmed, we typically require a deposit of 30%-50% to initiate the preparation of the goods. Upon completion of the products, we will provide video recordings, photographs, and other relevant documentation for you to verify that the goods meet your specifications.

If you have an agent or a third-party inspection company in China, we can arrange for them to visit our workshop for an inspection before the goods are finalized. Should any products fail to meet the specified requirements, we will address the issues and provide updated photos post-correction for your re-confirmation.

After the inspection is complete, please arrange for the remaining payment. We will then proceed with the loading or freight service to ensure the goods are delivered to you in optimal condition. Below are the payment methods we offer for your reference:

1.TT(Telegraphic Transfer) Company to Company

2. L/C (Letter of Credit)

3. credit cards

4. Paypal

The delivery time for custom whole house cabinets typically ranges from 30 to 60 days. This timeframe is subject to various factors that may influence the delivery schedule:

Design Phase: Upon receiving your initial information and requirements, we will promptly engage with the designer to create a preliminary design draft. This phase involves discussions, measurements, and revisions, which may take anywhere from a few days to several weeks, depending on the complexity of the design and the extent of modifications required.

Material Selection and Production: The production timeline can vary based on the availability of selected materials, the complexity of the production process, and the current workload of the workshop. While common materials and wood finishes are often in stock, custom or specialized materials may require additional time to procure and process. This stage can range from a few weeks to a few months, depending on these variables.

Please note that these timelines are estimates and may be adjusted based on specific project requirements and unforeseen circumstance

When deciding whether to buy finished cabinets from a store like Ikea or Home Depot, or to get custom cabinets, consider these key points:

Store-Bought Cabinets: These are pre-made and ready to go. They are usually less expensive and faster to get because they are mass-produced and available immediately. However, you may have fewer choices in terms of size, style, and finish.

Custom Cabinets: These are made specifically for your space and preferences. They can be tailored to fit your needs exactly, with a wide range of materials, styles, and finishes. The process takes longer (usually 30-60 days) and can be more expensive, but the result is a unique, personalized look.

In summary, if you need something quickly and at a lower cost, store-bought might be the way to go. If you want a perfect fit and personalized design, custom cabinets are worth considering.

Types of Materials Commonly Used for Cabinet Hardware

1.Copper

Quality: High-quality, durable, and corrosion-resistant.

Finishes: Available in polished, brushed, or antique finishes.

Advantages: Robust, with a classic appearance; can be plated with other finishes.

Considerations: Relatively high cost; suitable for projects where budget allows.

2.Stainless Steel

Quality: Superior material, known for its strength and durability; resistant to rust and corrosion.

Finishes: Offered in polished, brushed, or matte finishes.

Advantages: Provides a modern look; durable and low-maintenance.

3.Aluminum

Quality: Lightweight and commonly used in modern or industrial styles.

Finishes: Can be anodized or powder-coated.

Advantages: Rust-resistant, cost-effective, and versatile.

4.Zinc Alloy

Quality: Typically used for low to mid-range hardware; may exhibit wear and tear over time.

Surface Treatments: Can be plated or painted.

Advantages: Affordable and adaptable to various styles.

When choosing cabinet hardware, it’s important to consider not only the material, but also the quality of construction, finish, and how it complements the style of the cabinets. High-quality hardware is typically more durable and has a more refined look, while lower-quality options may be more budget-friendly but may lack in longevity and finish.

We'd Love To Hear From You

contact us

Find us Here

- Jihua 4 road, Chancheng District, Foshan City, Guangdong, China

Phone or Whatsapp

- +86 18029240327